I spent some time recently walking around town trying to get a battery replaced in my watch. After the fourth jewellers shop failed to remove the back was resided to sending it back to the manufacturer for repair. That was until I walked past the 3d printer in the office one day and had the idea to design make the tools to do the job myself, so off I went!

I spent some time recently walking around town trying to get

a battery replaced in my watch. After the fourth jewellers shop failed to

remove the back was resided to sending it back to the manufacturer for repair.

That was until I walked past the 3d printer in the office one day and had the

idea to design make the tools to do the job myself, so off I went!

Challenges

The watch has a screw off back and one issue that most of

the jewellers come across was getting sufficient purchase on the watch to

generate the torque required to remove the back.

Using a multipurpose tool also caused the tool to slip of

the watch when more force was being applied, basically because it wasn’t a

perfect fit. This risked scratching the back of the watch case, but more

crucially prevented proper engagement with the watch and made it impossible to

remove the watch back.

Another

hurdle I had to overcome was the limitations of the print material. I would be

using ABS filament. Printed in pins thin enough to engage with the watch case,

the material would not be strong enough to withstand the forces required to

open the back, so I needed to look elsewhere.

Solution

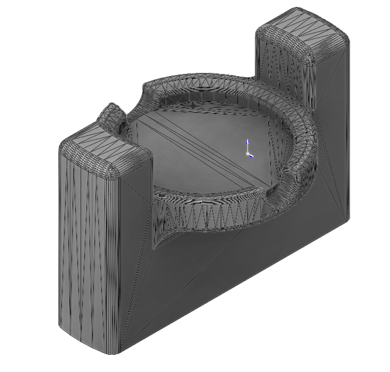

Naturally I began with SOLIDWORKS. I took some measurements

from the watch case and started modelling up the tools. I wanted to create a jig

that would hold the watch in position when enough force was applied to remove

the back and a tool to apply the force without slipping.

Holding Jig

For the holding jig, I made use of the shoulders of the watch

(I needed to remove the strap) as they were a solid fixed point that would

allow me to lever against. The rest was simply a case of allowing clearance for

the crown and making sure the watch glass was sufficiently protected by

allowing additional clearance so it wasn’t exposed to any pressure. Finally a block of material was extruded at

the base. The intention for this was to provide something to grip by hand or in

a vice if necessary.

The Removal tool

The tool itself was relatively simple. A pcd measurement was

taken from the watch and a series of holes patterned around the pcd to match

the points in the back of the watch case.

I found my solution for the pins in the form of some

stainless steel dowels from amazon.com. I wanted an interference fit between

the pins and the handle. The printer I used wasn’t accurate enough to warrant

specifying fit tolerances so I went with the nominal diameter of the pin (which

happened to work perfectly) but expected some fettling to get the pins

installed. The last thing was to add a handle to allow for sufficient leverage.

Having seen previous attempts with a steel tool fail, I went for something

quite chunky!

Design complete, it was ready for printing. I used

SOLIDWORKS to save my files to .stl format and loaded them into the 3D printers

processing software. When saving files for 3d printing it is important to save

to a resolution that best suits your 3d printer. Further information on this here.

My main consideration when nesting the parts was to ensure

the handle was facing upwards as this would ensure that there would be no

support material around the critical area where the holes would be (no fiddly

clean up afterwards), and that the holes would be printed as accurately as

possible.

Once printed the parts were removed from the bed and any

excess support material removed. With a little persuading the pins were

inserted and the tool was ready to go!

Installing the

battery

I removed the strap, sat the watch case in the jig, lined

the pins up with the watch case and twisted the back off with no problems.

From this point it was a case of replacing the battery,

giving the surfaces a clean and re-installing the watch back and strap.

Costing

Pins £4.20

Battery £2.50

Material 175g approx. £3.50

Total £10.20

All in all the DIY method was a similar in cost to having it

replaced in a jewellers, but significantly less than sending it off to be

replaced at the manufacturer!

3D Printing is becoming an increasingly popular method of

producing jigs and fixtures for manufacture. It allows for extremely quick

production of parts at relatively low cost compared to the machining of low

volume one off components. It also allows for the creation of impossible

geometries which can’t always be achieved using traditional manufacturing

methods allowing you to get creative!!

Nick Jones

SOLIDWORKS Application Engineer