Tuesday November 22, 2016 at 4:57pm

One of the many new features within the new release of SOLIDWORKS 2017 is the enhancements made to the wrap feature. Find out More about this enhancement in this blog post.

One of the many new features within the new release of SOLIDWORKS 2017 is the enhancements made to the wrap feature. The updates now

allows users to apply sketch geometry to all face types and multiple faces

simultaneously.

In this blog we will explore the options available to us in

the property manager of the wrap feature and how the different options will

create distinguishably different appearances to the final design. To express

this feature, we will look at the recently designed Solid Solutions Hover

Mower.

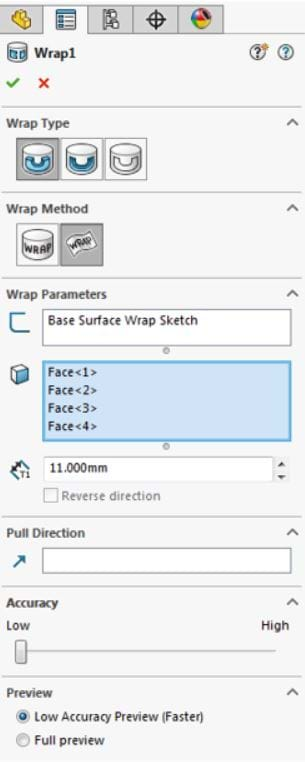

When in the property

manager of the wrap feature there are a number of options to choose from as

seen in the accompanying image:

Wrap type: the wrap type dictates the protrusion applied to the

sketch be it raised (emboss), indented (deboss) or simply imprinted on the

surface (Scribe)

Wrap Method: the two wrap methods include the traditional

analytical method whereby the sketch can be applied to cylindrical and conical

faces and the new Spline surface method, used when applying a sketch to any

face type.

Wrap Parameters: the selection made here define the sketch used

and the faces to which the sketch needs to be applied to. Finally, the

thickness value dictates the depth of the protrusion.

Pull Direction: this parameter determines the direction of the

protrusion. Should a plane be selected, then the direction of pull will always

be normal to the plane.

Accuracy: Controlled by a slider, this allows the user to

determine how accurately the sketch is mapped to the surface, with a greater

accuracy reducing the tolerance at which the defining geometry deviates from

the sketch.

Preview: as with other features this indicates how the

feature will look when applied to the model.

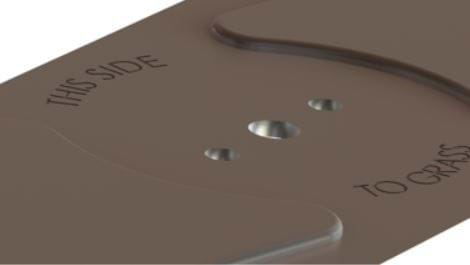

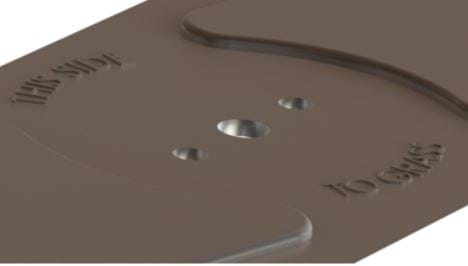

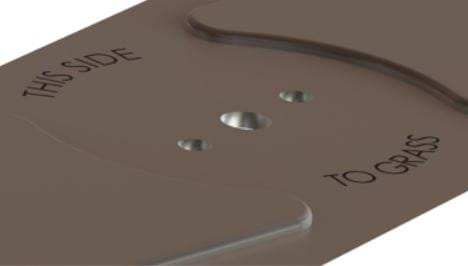

Within this case study of the Lawnmower, we can see how the various

options alter the design of the model. Below we can see an example of how the

wrap type varies from emboss, deboss and scribe when applied to the cutting

blade of the lawnmower.

The feature is used here to add detail and inform the

operator of the lawnmower the mounting orientation of the blade, should it be

removed from the device and replaced.

Deboss

Emboss

Scribe

Further to this the spline surface method was used to apply

the perforations to the surfaces of the grassbox. These perforations are

essential to the air flow through the system to drive the impeller which help

provide the lift for the lawnmower to hover. The design of the grassbox can be

seen below:

This conclude our summary of What’s New with the wrap tool in

SOLIDWORKS 2017. Go ahead and try it out for yourself!

By Jassim Alali

Applications Engineer