SOLIDWORKS SHEET METAL TOOLS CAN DESIGN PRODUCT PACKAGING

An egg of such grandeur deserves a luxury home.

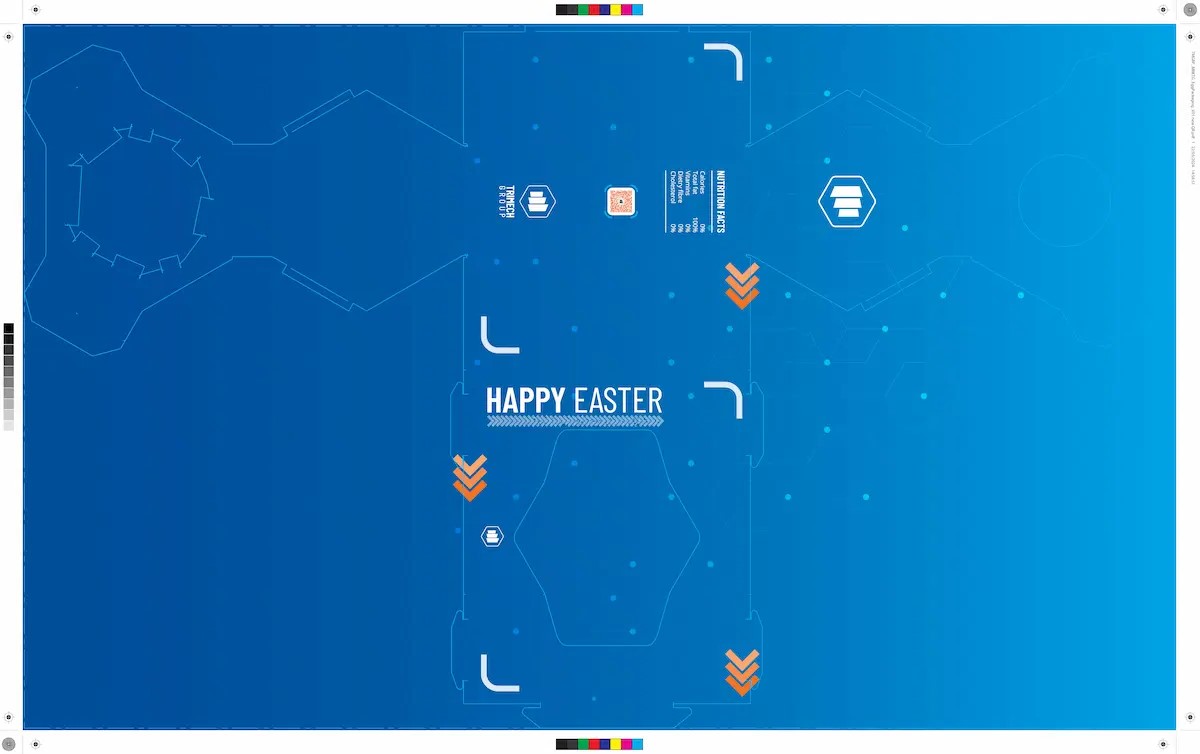

SOLIDWORKS Sheet Metal tools can be applied to a cardboard medium to produce intricate and functional packaging designs.

Employing multibody part design, we took the geometry of the egg to produce an accurate and parametric packaging design that can be easily updated if changes are needed and configured for different sizes.

To quickly create the correct basic geometry for the design, we created a simple solid hexagonal boss to enclose the whole egg, allowing space around the egg for packaging padding.

This provided us with our building block to convert the body into the outer shell of the packaging.

From there, we could extrapolate the internal structure required to support the egg and add the relevant tabs, slots, holes, and relief cuts with the standard sheet metal tools to ensure the shape could be created from a single flat net, without overlapping geometry.

Checking the sheet metal flat pattern regularly confirmed we were on the right track, with features such as edge flange letting us fold areas back on themselves to ensure the egg has a snug nest to rest in.

Creating the internal supports from cardboard meant we could reduce the amount of plastic needed in the packaging and maintain its recyclability.

EXPORTING THE FLAT PATTERN

Flat patterns can be exported easily from SOLIDWORKS using the export option from the right click menu of the flattened form.

Using the SOLIDWORKS Cloud Services, we delivered the net to our Graphics design team via the 3DEXPERIENCE platform.

SOLIDWORKS has plenty of tools to boost collaboration and speed up processes, and our Graphics team were able to produce stand-out packaging to catch the eye of the passing consumer.

If you are interested in packaging design, we have an upcoming webinar that will take you through some of the skills and techniques that we have at our disposal within the SOLIDWORKS suite.

If you are interested in packaging design, we have an upcoming webinar that will take you through some of the skills and techniques that we have at our disposal within the SOLIDWORKS suite.

Don't miss out, register now for our fantastic webinar

Using SOLIDWORKS in the packaging design industry DESIGNING THE MOULD IN SOLIDWORKS

After establishing the design of the egg, we needed to create the negative of the final product to create our mould.

By utilising draft analysis to determine where positive and negative draft would occur, we were able to extract the parting line with the use of the mould tool features.

From here, we created the parting line that we will use to define the two halves of the mould.

The flat base allows the egg to stand up by itself, but the geometric design of the base meant the parting surface was not as simple as your standard egg design.

I certainly don’t want to be the chicken that has to lay that.

Parting lines are easily generated with a single command to split the surfaces and identify where positive and negative draft occur – the path can be manually altered to achieve a clean end result.

No shut-off surfaces are required for this design, so we moved on to constructing the parting surface.

To construct the surface, we used the manual mode inside the parting surface tool to allow us to define how the surface extends from the parting line, ensuring the generated surface is larger than the intended mould size.

The Tooling Split command then automatically creates the folders and relevant bodies and surfaces for the mould in one swift operation.

This laid the foundations ready to be modified for manufacture.

If you are interested in learning more about mold tool design in SOLIDWORKS, check out our on-demand webinar Mastering mould tools and die design

USING SOLIDWORKS FOR SMALL BATCH AND LOWER VOLUME PRODUCTION

To manufacture our Easter egg, we enlisted the Solid Print3D team to produce the physical versions of our mould designs.

As fellow members of the TriMech Group, Solid Print3D are perfectly positioned to provide us with additive manufacturing solutions, offering a portfolio of best-in-class 3D printing, 3D scanning and workbench manufacturing solutions, across the UK, Ireland and Nordic regions.

We decided to implement a two-stage manufacturing process to create our mould.

Firstly, the mould was printed on the Formlabs Form 3L resin printer in High Temp resin. This resin was chosen because it is rigid and can withstand the temperatures of the pressure forming later in the process. Resin printing on the Form 3L results in a smooth high-quality finish - an important consideration as any layer lines or print imperfections would show in the final product.

We modified our mould design to make it more cost-effective, and under the advice of the Solid Print3D team, we added additional features to help reduce resin usage and incorporated perforations for the second stage of the manufacturing process.

For the second stage of the process, we opted to utilize the Mayku Multiplier pressure former.

This method allowed us to use food-grade thin material to form over our resin mould design.

We integrated ribs/support and location features into the mould design. All these features will transfer to the thin plastic shell to produce a semi-flexible mould.

This flexibility will compensate for the lack of negative draft on the embossed designs around the circumference of the egg, making it easy to release the final product from the mould.

Discover more about the versatile technology solutions used in this project, ideal for low-volume, high-accuracy production, over on the Solid Print3D website.

CONCLUSION

Thank you for joining in on the egg-citing Easter fun, it has been a cracking journey.

This design was created purely for some egg-stra fun, and the specialised techniques for optimising Easter egg manufacturing are certainly more complex than in this simplified design process.

That being said, the skills, principles, and techniques used, serve as a great example of what SOLIDWORKS can enable with a touch of creativity. SOLIDWORKS lays a robust foundation for fostering your design and innovation endeavours in the future, and we are here to support you throughout your journey.

As part of the TriMech group, we span multiple disciplines, from CAD and CAM to simulations, recruitment, consultancy, and manufacturing – we have teams of specialists ready to assist you with any and all of your CAD endeavours.

Interested in learning more about the TriMech group and how we can collaborate to bring your ideas to life? Reach out, and let's explore the possibilities of our partnership moving forward.