Monday January 6, 2014 at 5:00pm

On August 13th 2013 Guy Martin reached 112.94mph on bicycle cycling behind a modified racing truck at Pendine Sands, South Wales and became Britain’s fastest cyclist. For the preceding eight months Guy Martin had been working with Dr. Jason Hill of

Dynamiq Engineering Ltd (a

Solid Solutions customer) to develop the aerodynamic and structural modifications for the racing truck necessary to make this record breaking speed possible.

Dynamiq Engineering Ltd, were tasked by the production company to develop a suite of modifications to Dave Jenkin’s racing truck to create the largest possible slipstream, hence eliminating the aerodynamic drag that Guy Martin would have to overcome and allowing him the reach the record breaking speed of 112.94mph. The modifications involved the design, simulation and testing of a screen canopy to create the strongest possible aerodynamic recirculation behind the truck. The objective of the aerodynamic design was not only to eliminate drag, but if possible to create a positive thrust on Guy to help overcome rolling resistance.

Numerous canopy designs were considered, including partial and full enclosures, deflectors and simple screens.

3D CAD models of the truck and the canopies was developed in SOLIDWORKS and extensive engineering simulation carried out. Initially the simulation focused on

flow analysis to optimise the strength and scale of the wake generated by the truck. Transient flow simulations were carried out to capture the motion of the wake and help Guy visual the violently unsteady, chaotic and turbulent environment in which he was hoping to cycle at over 110mph.

It can be observed that the CFD gave good qualitative agreement between the wake shape and scale between the CFD flow visualisation and the images filmed by the aerial film crew capturing the record attempt for a TV series.

| .jpg) |

| Theory & Practise: CFD Simulations compared with the particle traces obtained by the sand becoming entrained in the wake of the vehicle. |

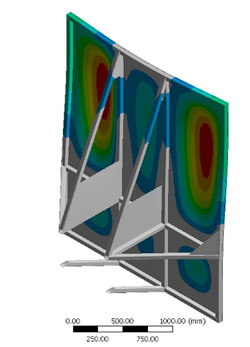

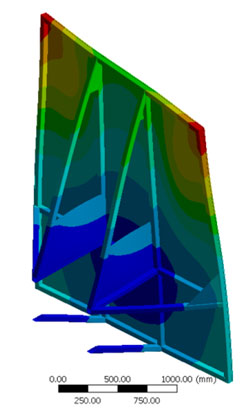

Once the technical decision had been taken to adopt a simple screen canopy and the performance calculations had shown that the racing truck would have sufficient power to be able to attain record-breaking speed with the additional aerodynamic drag, then the mechanical design and

simulation was undertaken. It was vital that the structure supporting the screen could handle the structural loads and avoid any potential vibration arising from such unsteady aerodynamic excitation.

Again a detailed 3D model of the underlying structure was developed in SOLIDWORKS and a detailed static structural and vibration analysis undertaken.

|  |

| (i) Static Structural Analysis | (ii) Modal Analysis |

The design was found to be strong and stiff enough to meet all of the required safety criteria and therefore fabrication of the prototype canopy was undertaken by the team at Jenkin’s Motorsport.

Once complete the canopy was subjected to a one-day test program from both an aerodynamic and structural perspective at a dis-used aerodrome in Staffordshire, UK. Initially, the canopy was attached to the truck a series of runs made at progressively higher speeds along the two-mile run-way with structural inspections being carried out in between each run.

Once it had been determined that the canopy structure was adequate, ribbons were attached to the rear of the screen the help visualised the flow field behind the truck. The CFD suggested that the flow on the face of the canopy would be directed forward in the direction of travel and then outwards along the board, therefore if the aerodynamics were working as planned the ribbons should have been extensive pinned to the back of the canopy.

|

|

| Testing: Ribbons were attached to the rear of the screen to help visualise the flow behind the screen. At all speeds above 40mph the ribbons were seen to be pinned to the back of the canopy exactly as-designed and simulated. |

With all of the testing complete and the truck working as designed the date for the record attempt was set for August 13th 2013 at Pendine Sands in South Wales, UK.

Originally it had been planned to attempt the record at a UK-based proving ground on an oval concrete track, but at the last minute this had to be abandoned due to safety concerns. The only other location deemed suitable was Pendine Sands. A hard tidal sand beach used as a weapons testing range and owned by the UK ministry of defence. The beach was far from ideal from the point of view of the record attempt. The higher rolling resistance and lower traction of the surface made attaining the record speed far more difficult and the stability of both vehicles was also substantially reduced. Furthermore, as the beach dried out during the day, loose sand was entrained into the recirculating wake of the truck reducing visibility behind the canopy at times to around 1m.

However, despite all of these factors just after lunch Guy Martin rode his bespoke bicycle millimetres from the back of the truck and attained a maximum speed of 112.94mph, becoming Britain’s fastest ever cyclist.

When the telemetry data was analysed after the record breaking run, it showed that Guy had ridden his bike at over 100mph for well over a mile, in near zero visibility, on an extremely unstable surface, less than 500mm away from a 5 tonne racing truck.

This record attempts forms part of a 4-program series currently being shown in the UK on Channel 4, in which Guy Martin attempts to break four speed related records including, outright speed on a bicycle, hydroplaning a motorcycle, fastest human powered flight and downhill sledging. These series can be viewed online at:

http://www.channel4.com/programmes/speed-with-guy-martin

While there is no doubt that the success of this record on the day was due to Guy’s skill and experience in handling the bike under incredibly difficult circumstances, the record itself was made possible and all of the risks minimised through the extensive use of 3D CAD, finite element analysis and computational fluid dynamics by engineers with the expertise to use the technology correctly.

by Dr. Jason L Hill

Solid Solutions Customer