The SOLIDWORKS Defeature tool is a technique that can be used to simplify assembly components, as it enables you to remove details from a part of an assembly.

Defeature tool is a

technique that can be used to simplify assembly components, as it enables you

to remove details from a part of an assembly. You can save the less-detailed

model to a separate file and maintain references to the original part or

assembly. Defeature helps reduce file size to improve performance with large

models. The new file has the same mass and centre of gravity as assigned mass

properties. This tool is often used to remove proprietary information you would

not like others to see and share files without revealing all the design details

of the model. This in turn will also speed up your open/rebuild times.

Defeature functionality includes

the ability to:

- Remove

internal detail in a design

- Remove small

features below a user-defined value

- Preserve

necessary functional holes and features

- Maintain

relative motion between parts without the internal details

- Save your

assembly as a single part

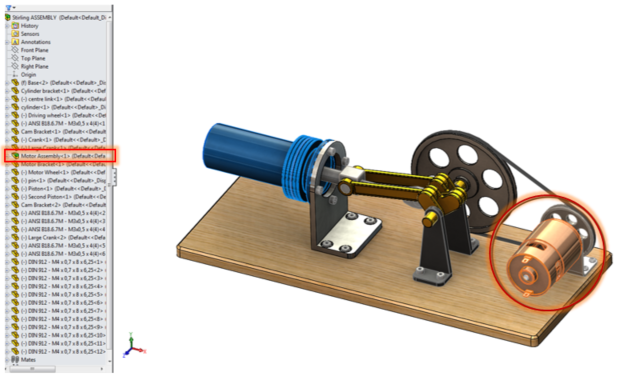

The image below is a Stirling

engine assembly that contains a subassembly where the Defeature tool can be

used.

Open the subassembly and you can

see that the motor sub assembly consists of 4 parts that are mated in place.

The defeature tool is under

Tool > Defeature

The image below shows the

first screen of the Defeature tool and the selection for this assembly.

1.

Internal Components: This selection allows Defeature

to remove any internal component that is inside your assembly.

2.

Small Components: This selection will allow you

to specify a percentage and any component that is smaller than that percentage

will be removed.

3.

Display: This option will allow you to see all the

components, which components are being removed, or which components are left

behind.

4.

Exceptions: Components selected in this box will not be

removed.

5.

Section View: This option enables you to

temporally section the assembly to help see the inside of our assembly and

select certain components.

6. Next: Moves to the next screen of the

Defeature tool.

The second screen of the

Defeature tool enable you to create a group of componments that have no

movement between them and it enables you to list out any mates that Defeature assumes you will want to

maintain between your groups.

Motion is not required for

this subassembly. Click Next

The

image below shows the the third screen of the Defeaure tool which enables you

to keep any specific features in the model. For this model I have select the

the two holes highlighted to keep as the are used in the main stirling engine

assemble to mate the motor in place.

1. Features

to Keep: This

box will allow you to keep features that are important to your model. (In this

example, the selected holes)

2. Select All Holes: All the holes in the assembly/part will be

selected to be removed.

3.

Select

holes between: You

can determine a size range to determine which holes are removed.

The next

screen will bring up a will show you the final comparison between the

original model and the Defeature version. Notice the Defeature model many

features have been removed and the simplified version is now a part file.

Select the ‘save the file as a separate file’ and when

you hit the tick, it will open the

window shown below and ask you to save the simplified model.

We can now use the ‘Defeature’ part to replace the motor

assembly, so right click on the assembly and you can select ‘replace

components’

Select the Defeature part and select the appropriate mates.

The holes that were excluded in the Defeature tool are now used to mate the part to the assembly.

The image below shows the motor subassembly has been

replaced with the Defeature part.

Using the AssemblyXpert, you can see the effect

this has had on the rebuild time of the Stirling engine assembly. There is a

decrease in the rebuild/ loading time.

Before After

Bismaya Sabu

Applications Engineer