Now the 2016 Summer Olympics in Rio is over, we can reflect on the strength and determination athletes require to compete and be the best in the world. Using SOLIDWORKS Simulation we'll take a look at how an Olympic barbell is loaded for world record attempts and is engineered to be safe enough to be able to withstand the best that Olympians can throw at it.

It’s

always intriguing to witness the strength of Olympic athletes competing in

sports such as weightlifting. But how often do we stop and consider the

strength and safety of the Olympic equipment in use? Suspending hundreds of

kilograms above your head is never a good idea if you’re not sure how well the

equipment will hold up so let’s see how we can use SOLIDWORKS Simulation to

help us understand how strong an Olympic spec barbell really is...

Loading Scenarios Tested:

-

Static (500kg and with

remote load support)

SPECIFICATION:

The first step was to model an Olympic

bar alongside a set of standard weights according to Olympic/IWF specifications

(weight designated by colour) using SOLIDWORKS. The extensive SOLIDWORKS materials

library provided the properties for each component of the assembly. Utilising the

Mass Properties and Measure tools allowed the volumetric dimensions of the

parts to be modified to meet weight specifications.

Barbell: Stainless Steel [28mm diameter, 2m length, 20kg Total]

Barbell Ends: Chrome Steel [50mm diameter to fit weights]

Weights: Rubber Coated Grey Cast Iron [50mm centre hole, 450mm

diameter]

THE CURRENT RECORD:

The current Olympic record for weight lifted was

approximately 263kg in Athens 2004 by the powerhouse Hossein Rezazadeh in the

clean and jerk event. Modelling the complete lift would be better suited to a

SOLIDWORKS Motion Analysis study. However, in this case in order to see the

forces this would exert on the barbell using SOLIDWORKS Simulation we would use

a snapshot of the lift at a key point at which the barbell would be fully

suspended above the head.

SIMULATION:

A static simulation was conducted

at first by rigidly fixing the bar at the centre, representing it as a loaded

beam and applying a symmetry condition to model only considering one half of

the bar. It was then possible to extract the resultant displacements alongside reaction

forces under applied gravity.

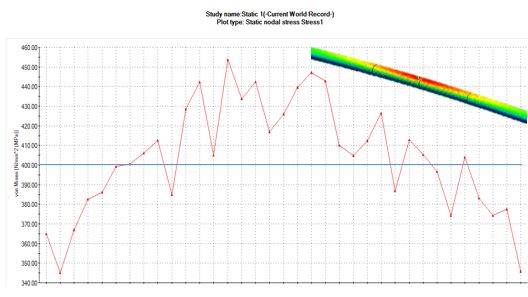

Utilising the graphical output

option in the probe tool, the distribution of stress at a selection of points around

the centre of the bar could be identified. Maximum stress under these

conditions was 461MPA (400 average) resulting in around a 5 cm deflection at

the tips.

The

stainless steel bar has a yield strength of around 513 MPa and from the first

result the skin stress was approaching the plastic deformation region but to

see the extent of this, the mesh sectioning or section clipping options could be

used to see the stress through the cross section ensuring it stays below the

max allowable stress.

Typical Olympic bars are rated to a maximum of 700kg

before failure.

Applying 20 x 25 kg weights took

the total weight of the barbell to over 500 kg at which point Herculean

strength would be required to lift this above the average human head however

the bar still managed to withstand the loads exerted as seen by the Stress

plot. Deflections at the extreme ends of the bar were 80mm which would be quite

evident when lifting. Repeated lifts of the bar would potentially result in the

bar not returning to its original shape having plastically deformed but would

be understood better through a fatigue study.

In

SOLIDWORKS 2016 the ability to section meshes provides useful insight in to

the stresses inside the bar through the cross sectional elements in 3D. This

ensures that a fine enough mesh is being used to capture the behaviour inside a

part or component and be refined if required. These options are found under the

mesh quality entry or under the results context menu in the simulation tree.

Using this tool, it is possible to analyse the barbell and clearly see the high

tensile and compressive stresses at top and bottom (outer radial region) of the

bar.

So far only rigid constraints from the centre were

considered as it’s often difficult to accurately represent the changing

constraints on the barbell when being lifted at any point during the clean and

jerk (suspended above the head for example). One way to overcome this is

through the use of remote loads to represent the forces and contact conditions indirectly

exerted on the bar. For example, the reaction force of an athlete supporting

the bar hence counteracting the weight force to some degree without applying

additional contact constraints to the bar.

This ensured that the model would

not be over constrained by rigidly fixing it in the areas where some movement

would still occur (e.g. holding the bar at the grip handles). Why? Because over

constraining meant a reduction in degrees of freedom at nodes along the bar

that should otherwise be free to move. Doing so would me a reduction in how

accurately the load was distributed through the entire span of the barbell and

key information about how the barbell behaved when loaded would be lost in the

simulation.

Assuming a super Olympian thrust

the bar vertically upwards with an acceleration of 0.5 m/s^2 with a split

second force of 5370N the barbell would still be able to withstand the load

with around 520MPa max tensile stress and an 8cm deflection at the tips as seen

by this simulation. Under these extreme conditions a safety factor plot could

be used to explore the distribution of material strength with respect to the

loading conditions. Whilst the outer surface of the barbell showed a high

stress concentration, the rest of the bar was able to withstand the forces and

remained in a safe region.

To summarise, we have seen how we can use a variety of

SOLIDWORKS tools with a simple static set of simulations to see if the

performance of the barbell is up to par with the performance of Olympians. It’s

safe to say that the next person to break the record doesn’t need to worry

about breaking the bar, even if they manage to raise it…

Sameer Qureshi

Applications Engineer