Wednesday March 29, 2017 at 3:26pm

Applications Engineer, Rory Niles takes us through his latest blog 'Confusing Configurations' in an effort to help save you time whilst configuring your parts.

Confusing

Configurations?

If you do a

range of similar products, you will know that configurations of your parts will

save you a whole lot of work on a daily basis, but once you have started

putting these parts into assemblies it can get confusing.

Basically, the possibilities all multiply, as does the potential for selecting

and changing the wrong thing…

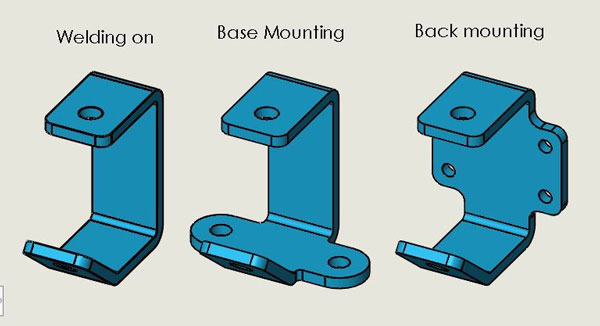

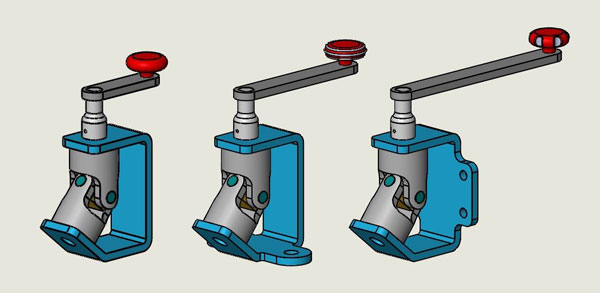

Here we have

a “Bracket” part with some configurations in it: -

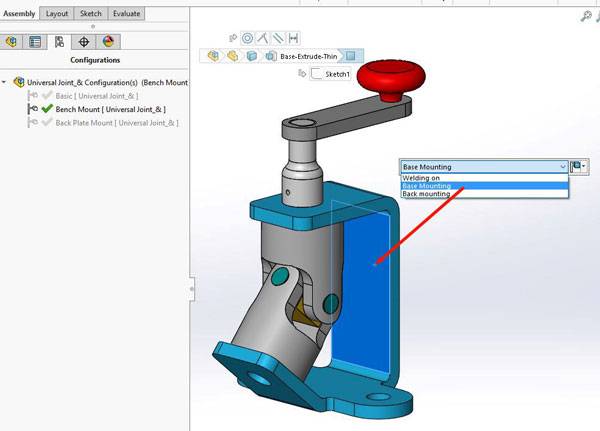

This has

been used in an assembly (that may be vaguely familiar to many of you), and as

you can see from the picture, I have created some configurations in that top

level assembly called “Basic,” “Bench Mount” and “Back Plate Mount,” and I have

just selected the Bracket on screen and used the drop down list to swap the

configuration of the part that is used in each configuration of the assembly: -

That to me

is the simplest way of doing it – and that’s what I’m after here.

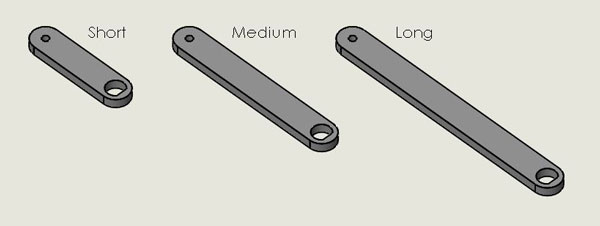

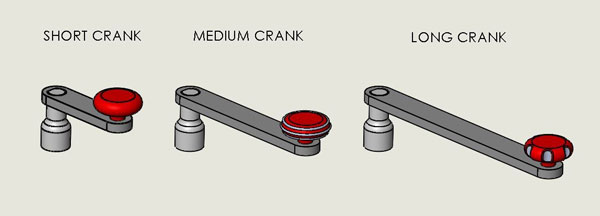

I also have

some other parts with configurations, the “Crank arm”: -

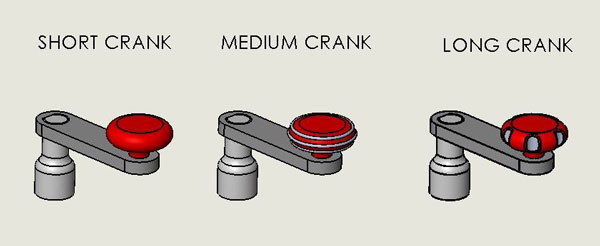

And the

“Knob”: -

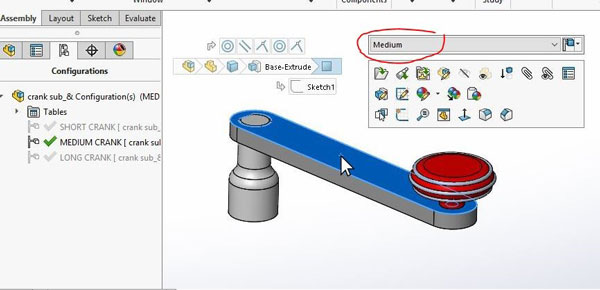

I have

fitted these together in another assembly, called “crank sub”,

I then created configurations of this assembly, and I just used the drop down

selection list to swap the configurations of the parts that the assembly configurations

use: -

So now my “crank sub” assembly has these

combinations: -

Great, so far so good.

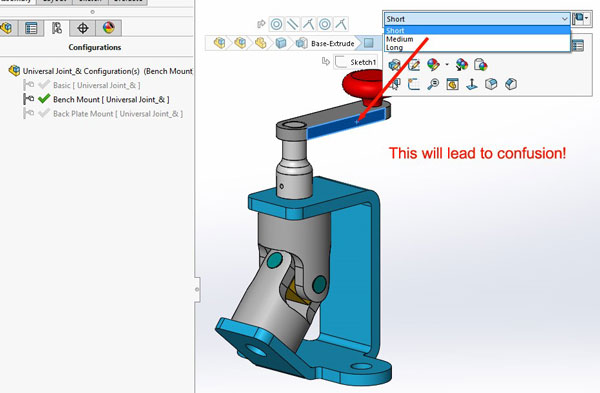

It is when the “crank sub” is put in

the top level assembly “Universal Joint”

that there is the potential for confusion!

I want a

range of Universal Joints with different cranks, the important thing to note is

that it makes a big difference where you

select things!

You really

don’t want to select parts that are inside the sub assembly from the graphics

area of the screen when looking at the main assembly, and switch their

configurations from the drop-down list – like this: -

By selecting

that part on screen I would be

changing the configuration of the part that is being used by the currently selected configuration of the sub assembly!

In other

words I would be in effect editing the

sub assembly, and I could get something like this if I was to go ahead:

-

Which is not

what I want at all!

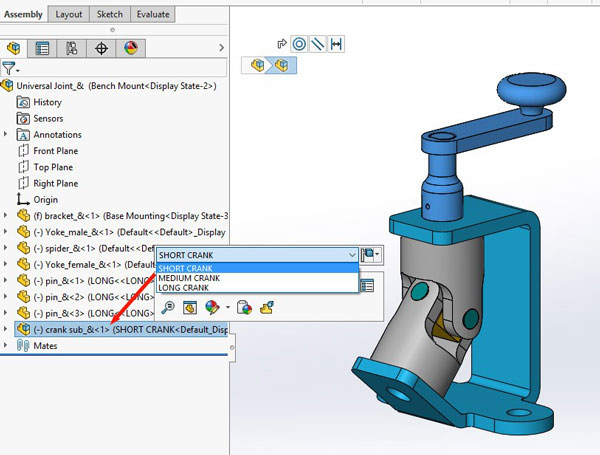

What I

should do from the main assembly (once I have corrected the configurations in

the sub assembly!) is select the name of the sub assembly from the

design tree: -

Then I am

selecting the existing configurations of the sub assembly that the main

assembly will use – then I can get my full range of different machines: -

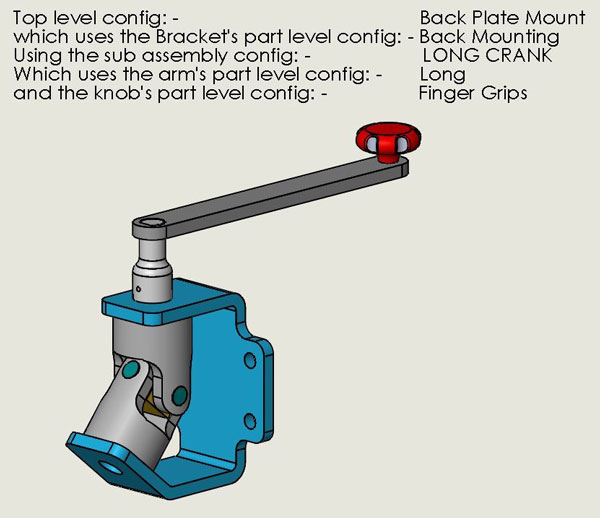

So this is

how it breaks down: -

If in any

doubt open up each level (part/sub assembly/top level assembly) and follow it

through…

And if you

want to change what configuration of your sub assembly is being used by your

main assembly select its name from the tree!

I hope that

helps!

Rory Niles.